PRODUCT

Fit to small/medium volume spot varnish and foil stamping on color printed paper by indigo or various digital color printer. No laminating process in advance is needed.

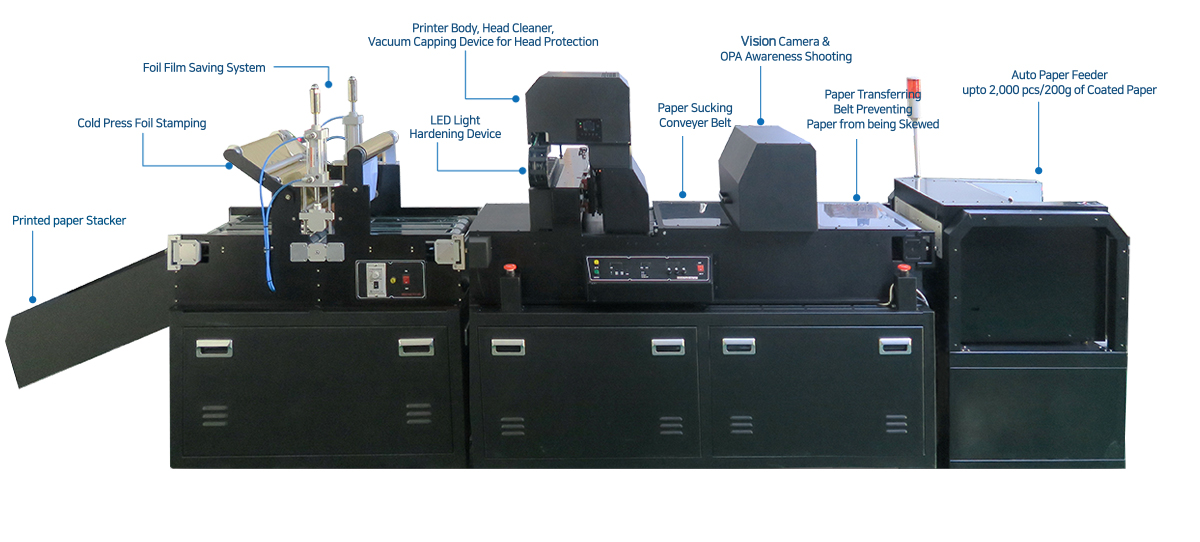

Model : AFV6

- Printer Specification

-

- Head

- 6 Heads(Ricoh Gen 5)

- Ink

- 2L Container Pump System (Refillable)

- Power Supply

- AC 220V Single-Phase

- Body Size

- L 3840mm, W 1100mm, H 1300mm

- Body Weight

- 400 KG

- Power Consumption

- 4 KW

- Printing Features

-

- Function

- UV Spot Varnish and Foiling (Gold, Silver)

- Printing Speed

- Max 3 sec/Paper, 1,200 pcs/1 hr

- Spot Varnish Thickness

- 30 ~ 80μ

- Printing Materials

- Max 330 x 500mm, Min 297 x 300mm

- Paper Thickness

- 135g ~ 450g

- Printing Type

- Single Pass

- Printing Method

- OPA Mark Shooting widh CCD

- Resolutio

- 600x600dpi / 600x2400dpi / 600x4800dpi

- Printing Area

- Max 324mm x 488mm

- Paper Supply

- 2,000pcs based on 200gCoated Paper

- | Printer Structure

-

- Auto Paper Feeder + Paper Vacuum Suction Conveyor Belt + Main Body (Vision Camera + UV Printer + Head Cleaner + Vacuum Capping Device for Head Protection) + Foil Pressing

- PC + Beatus RIP Software + 2.5HP Air Compressor etc - | Printing Quality

- - Placing Inkjet Head(Ricoh Gen.5) and LED Light Hardening Device in Close Makes UV Ink Hardening Quickly - Minimize UV Ink Running While Injection / Perfect Printing result in Text, Image end Edge

- | Powerful Head Cleaner & Head Protection Device

- - Minimize Ink Consumption for Head Cleaning with Cutting Edge Capping/Wiping System - Head Clogging Free while not in use with Vaccum Compression

- | Foil Film Saving System

- Foil Film Saving by Adopting Foiling Area Recognition System

- | UV Coating Thickness Adjustable

- Ink Injection Amount Adjustable in 3 Steps Makes UV Coating Thickness as Operator Wants

- | Cold Foil Stamping

- Adopt Cold Press Foiling in Order To Avoid Printing Material Deformation and Foil Stamping Defects

- | Vision Camera System

- - Adjust Printing Position by Shooting 2 OPA Marks for Every Printing Material - Vision Camera Shooting Results are Displayed on Monitor

- | Minimize Job Change Time

- Wide Range of OPA Awareness by Vision Camera Makes Job Change Easy end Job Change time Short Without Additional Vision Camera Position Adjustment

- | Beatus-Owned Technology of Printing Material Transferring Conveyor

- Beatus-Owned Conveyor Technology Minimizes the Skew during Transferring Printing Materials on Conveyor While the Others Do Not

- | Minimal Body Size and Energy Consumption

- Less Spacs Needed for Installation and Single-Phase 220V 4Kw

* Made in Korea(BEATUS)